Ashok Leyland Trucks in India 2020

ASHOK LEYLAND TRUCKS IN INDIA 2020WITH PRICE, SPECIFICATIONS & APPLICATIONS ASHOK LEYLAND TRUCKS IN BS6 RANGE Ashok Leyland Trucks like

You are out on a Trip for Business or Pleasure, in the Middle of the Night when you’ve been Driving Continuously for around 6-8 Hrs. Suddenly, you Find that one of your Vehicle’s Headlight Bulbs have Fused and not working at all. Even more Frustrating is the Fact that you have no Help available in the Pitch Dark to Temporarily sort out the Problem for you. You feel disappointed at the Quality of the Bulbs and decide to Purchase a Better Quality Bulb next Time around only to find the Same Problem Occurring every 2-3 Months. You Finally Quit and decide there is no Solution to the Problem. SOUNDS FAMILIAR???

WAIT! THERE IS A LOT MORE TO IT THAN MEETS THE EYE…..

The Problem Lies in your Vehicle’s Electrical System for which the Bulb Holder or Bulb Socket is the Most Important aspect.

People Driving on the Highways are usually using Higher Wattages Bulb for their Cars like 100/ 90 Watts or 130/ 100 Watts for Better Vision. The Stock Bulbs in your Vehicle when you Purchase them are in 60/ 55 Watts and thus the Electrical Wirings are Installed to Support the Load of Only 60/ 55 Watt Bulbs.

When Users Upgrade their Vehicle Bulbs from 60/ 55 Watts to 100/ 90 Watts or say 130/ 100 Watts, they are Neglecting the Increase in Load on their Electrical System by Virtue of Greater Flow of Current to the Bulbs & The Excess Amount of Heat Produced by those Higher Wattage Bulbs.

WHAT IMPACT DOES IT HAVE?

The Result is that the Bulb Holders in your Vehicle will not be able to take the Load of the Increased Bulb Wattage, as there is almost Twice More Heat Produced and Current being Passed. This is the Time, When you Truly put your Bulb Holders to Test. The Results are

This is a Process that Occurs Over & Over, You Keep Wondering that it’s your Vehicle’s Bulb that are not Good Enough but it’s Actually the Bulb Holder which is at Fault. In Some Cases, People End up Changing the Bulb and keep using the Damaged Bulb Holder only to make Matters Worse.

Along with the Bulb Holders, The Dual Head Lamp Relay also needs to be Robust to Support the Needs of the Higher Bulb Wattages. In Most Cases, around 80% Users Complaint of the Wires of their Car or the Wiring Harness Kit installed getting Heated to Dangerous Extents which may Lead to a Fatal Accident Specially on Highways at Such High Speeds.

You May Wonder, We are Buying the Bulb Holders in Ceramic which has a Very High Melting Point. Then why is it Melting?

The Answer to that is in the Contact Points that you will Read more About below…

Getting Straight to the Point, Recommendation is to use a Bulb Holder and Wiring Kit which has the Following Qualities:

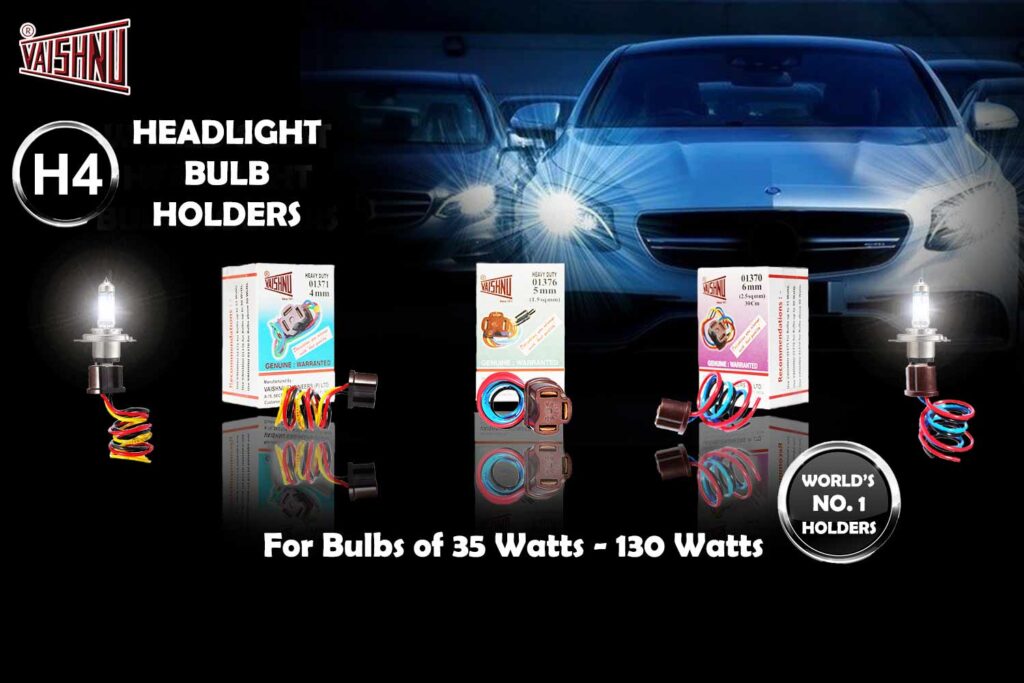

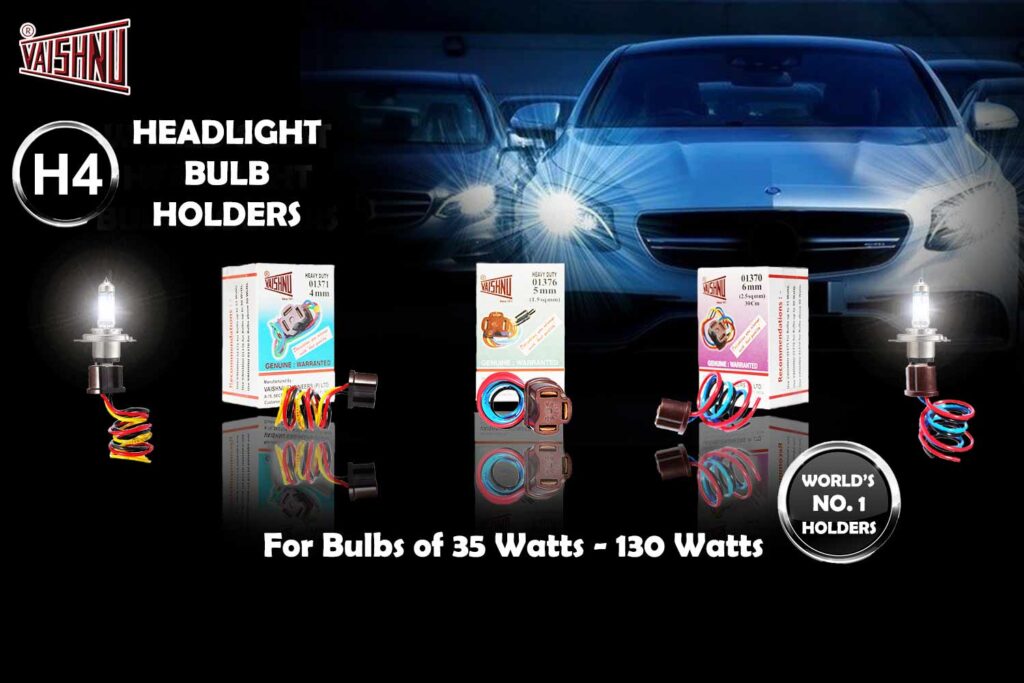

We are One of the Leaders in the Automotive Industry Since 1971. It is our Hard work over 49+ Years that has helped us Achieve Near Perfection in the Manufacturing of Auto Electrical Products. ‘VAISHNU’ Bulb Holders are Personified as ‘THE BEST’ in the WORLD with Customers once using it, Never asking for any other Brand ever again.

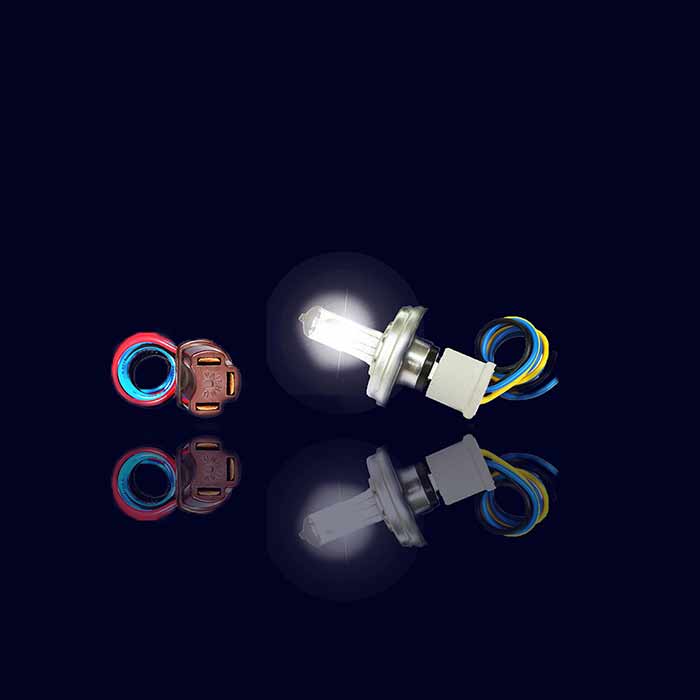

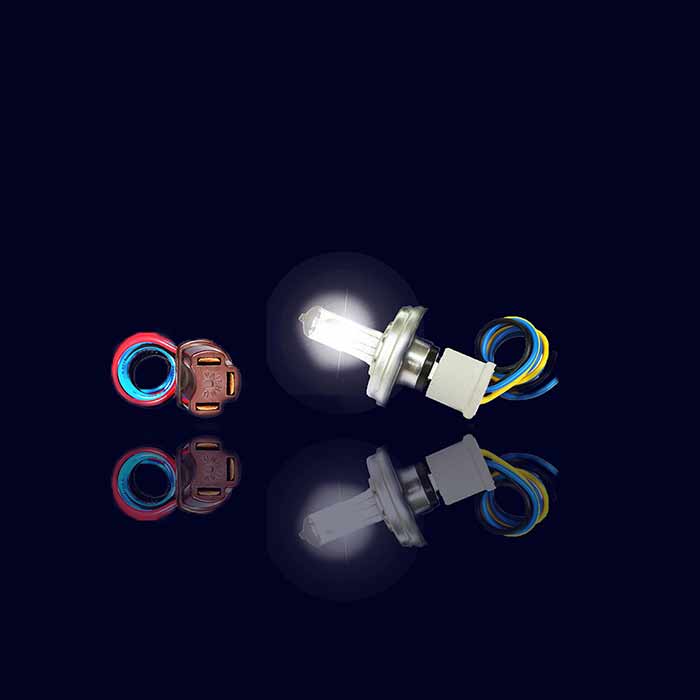

‘VAISHNU’ Bulb Holders are unlike any other Brand in the Market with PB Contact Points for Bulb Terminals. You will usually Find in the Market Ceramic Holders with Brass Contacts. These Holders are not Feasible to withstand Higher Loads of Heat & Current through the Brass Contacts and therefore do not Perform even in the Presence of Ceramic Body. When the Bulb stays on Continuously for 6-8 Hrs, the Immense Heat makes the Brass Contacts loose and Causes Sparking and Fusing of Bulbs.

‘VAISHNU’ Holders are in PB Contacts which has a Much Better Heat Insulation and therefore does not even Melt on Colossal Heat. Moreover, The Holders Contacts are Built in with a Special Spring Technology which does not Loose it’s Grip even in the Most Adverse Conditions Preventing any Sparking thus any Fusing of Bulbs.

The NO.1 Reason for any Electrical Connection Failure is Loose Connection. ‘VAISHNU’ Holders are Specifically Designed to Eliminate any such Faults and Provides Longest Life to your Bulbs.

This is the Actual Reason that Despite Using Ceramic Holders, your Headlight Holders are Not doing the Job they are Meant to do and Fusing your Bulbs. Compare with the Best in your Opinion, you will Feel the Difference.

A Common Reason for Bulbs to Fuse is when the Current Carrying Cables of the H4 Headlight Bulb Holders are unable to supply Constant Electricity supply to the Bulbs leading to Fluctuations and ultimately leading to Bulbs Fusing.

‘VAISHNU’ H4 Headlight Holders are made of Finolex Cables with High Copper Density per sq. mm of Cables. Higher Copper Strings and lesser PVC Material in each of our Bulb Holders leads to Smooth & Uninterrupted Supply of Current through to the Bulbs.

You will find in the Market, most Holders are very Thick but that Thickness is with 80% PVC and only 20% Copper.

In ‘VAISHNU’ Holders you will Find Maximum Copper Density per Sq. mm of Cables. (Best in India)

Available in BAKELITE & CERAMIC which are Excellent For Heat Absorption.

‘VAISHNU’ Holders can absorb High Heat for Periods of over 12 Hrs of Continuous Heat.

Bulbs Produce High Heat over prolonged use, Bakelite & Ceramic absorb that Heat quite Easily. Although its a General Trend in the Industry to use Ceramic Holders since it has 2000 Degree Celsius of Melting Point.

We Recommend to Customers to use ‘VAISHNU’ Bakelite Holders for Superior Performance as Bakelite has:

We have Developed Different Models for Different Wattage of Bulbs as per the Customers Needs.

We are An ISO 9001: 2015 Certified Company, Following Strict Quality Norms to ensure our Customers receive ‘ONLY: THE BEST’ Products.

Tier – 1 O.E.M. Suppliers in the Past, The Organization Follows Strict Protocols of 3 Tier Quality Inspection from Purchase – Production – Packaging, Ensuring Customers Receive Only 100% Tested & Genuine Products.

ASHOK LEYLAND TRUCKS IN INDIA 2020WITH PRICE, SPECIFICATIONS & APPLICATIONS ASHOK LEYLAND TRUCKS IN BS6 RANGE Ashok Leyland Trucks like

BEST TRUCKS IN INDIA 2020 BS 6 Compliant TOP 5 BEST TRUCKS IN INDIA - HEAVY DUTY No MANUFACTURER MODEL

top 5 tipper trucks in india - 2020 (bs-6) Here is the List of the Top 5 Tipper Trucks in

TIRED OF REPLACING HEADLIGHT BULBS? First lets Talk about a Common Experience that most of us 'Adventure Lovers' have faced